Services

Powder Reconditioning

At AP&C, powder recycling by blending is available for its customers to support the sustainability of their businesses.

AP&C chose this process because it minimizes energy consumption. This method does not require remelting the powder; instead, it allows the powder to achieve acceptable chemistry by blending virgin and used powder. This process extends the lifecycle of the powder, reduces costs for the end user, and positively impacts the environment by decreasing material waste and energy consumption.

AP&C chose this process because it minimizes energy consumption. This method does not require remelting the powder; instead, it allows the powder to achieve acceptable chemistry by blending virgin and used powder. This process extends the lifecycle of the powder, reduces costs for the end user, and positively impacts the environment by decreasing material waste and energy consumption.

Custom atomization

AP&C atomization services are suitable for high melting point and reactive materials. Our powders, manufactured using the proprietary APATM Plasma Atomization process, are highly spherical and contain virtually no entrapped porosities. Additionally, they possess minimal satellite content, resulting in exceptional flowability and packing density.

Contact your AP&C powder expert for more details on atomization services and minimum order quantities.

Contact your AP&C powder expert for more details on atomization services and minimum order quantities.

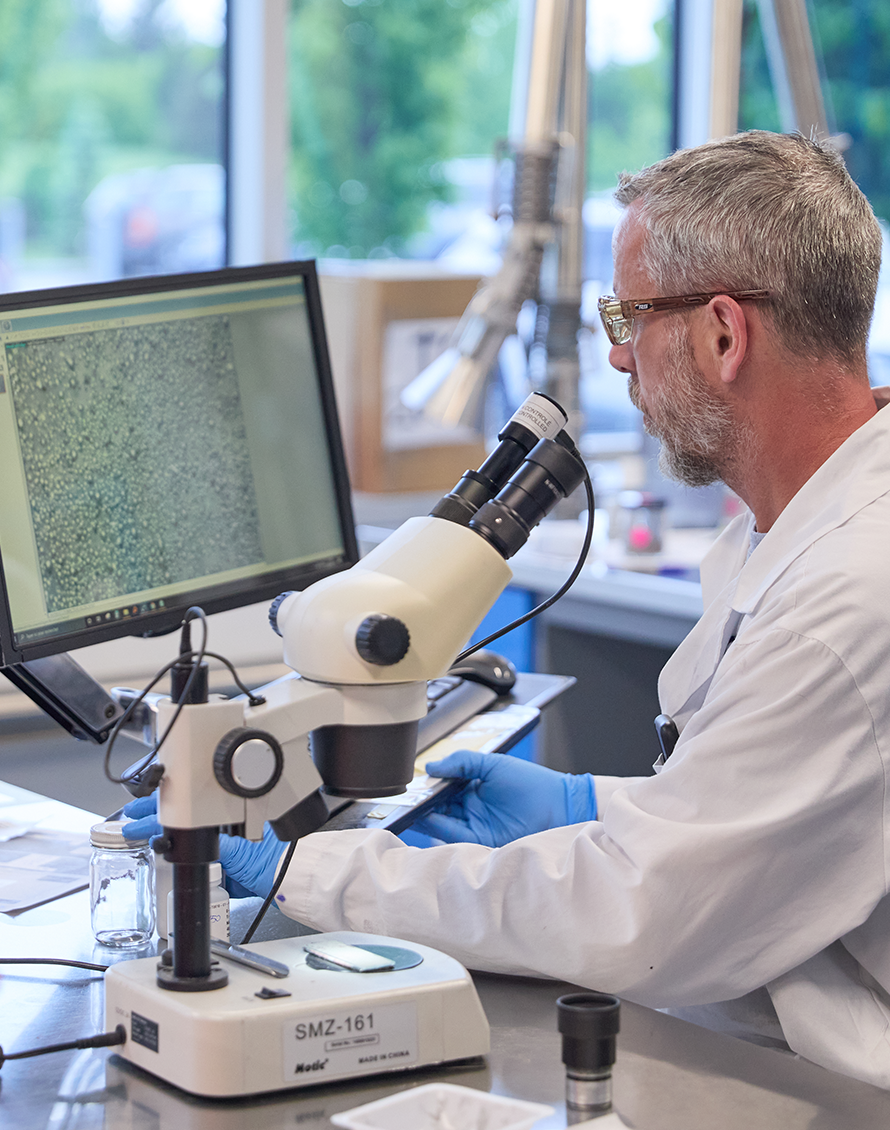

Powder testing

AP&C's ISO 17025 certified laboratory offers comprehensive powder testing services. These services include analysis of chemical composition, particle size distribution (PSD), flowability, apparent density, tap density, and CT scanning.

Contact your AP&C powder expert for more details on our powder testing services

Contact your AP&C powder expert for more details on our powder testing services