Ti-6Al-4V

grade 23 (ELI)

Titanium alloy

Ti-6Al-4V grade 23

AP&C's leading product, Ti-6Al-4V Grade 23, is renowned for its outstanding strength-to-weight ratio, making it ideal for a wide range of applications in both the medical and aerospace industries.

Powder chemical composition may comply with standards: ASTM B348, ASTM F136, ASTM F1472, ASTM F1580, ASTM F3001, ASTM F3302, AMS7017 or equivalent standard.

Powder chemical composition may comply with standards: ASTM B348, ASTM F136, ASTM F1472, ASTM F1580, ASTM F3001, ASTM F3302, AMS7017 or equivalent standard.

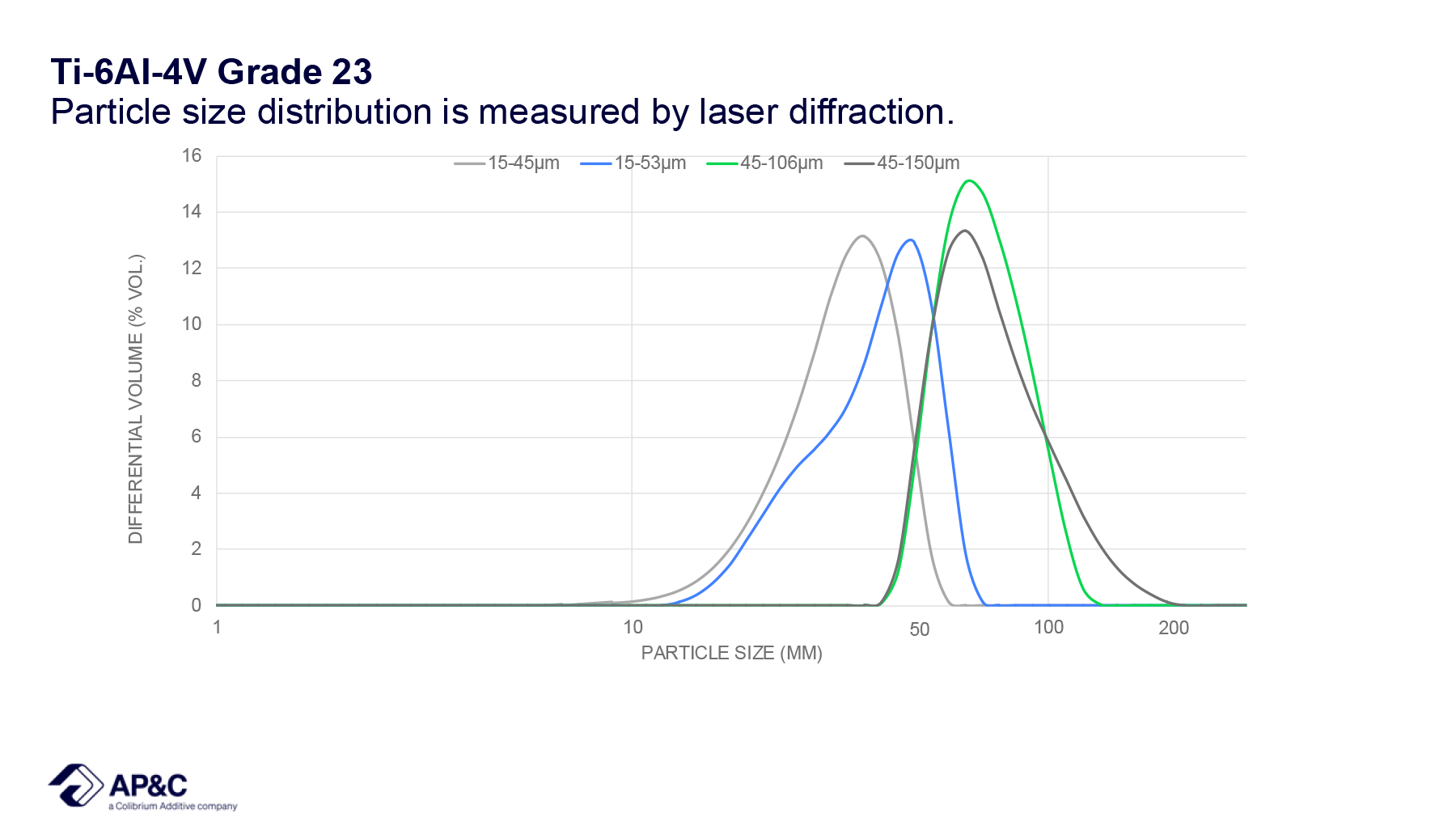

Particle size distribution

15-45 µm

20-63 µm

45-106µm

45-150 µm

Typical values

PSD

Size distribution by laser diffraction (ASTM B822)

Apparent density (ASTM B212)

Flow rate (ASTM B213)

Oxygen content

Application Technology

D10

D50

D90

15-45 µm

20 µm

34 µm

44 µm

2.49

g/cm 3

g/cm 3

28 s

0.10 w%

L-PBF

15-53 µm

22 µm

39 µm

54 µm

2.52

g/cm 3

g/cm 3

28 s

0.10 w%

L-PBF

20-63 µm

26 µm

46 µm

60 µm

2.57

g/cm 3

g/cm 3

28 s

0.09 w%

L-PBF

15-106 µm

27 µm

54 µm

88 µm

2.61

g/cm 3

g/cm 3

25 s

0.08 w%

L-PBF

45-106 µm

52 µm

71 µm

102 µm

2.47

g/cm 3

g/cm 3

25 s

0.08 w%

EB-PBF, L-PBF, DED

45-150

54 µm

85 µm

141 µm

2.59

g/cm 3

g/cm 3

25 s

0.08 w%

DED

Various particle sizes are available upon request

Ti-6Al-4V grade 23 offers outstanding biocompatibility, making it perfect for medical implants. Its superior corrosion resistance ensures longevity and reliability in demanding environments. This alloy is widely used in the aerospace industry for critical components, in the medical field for durable implants, and in high-performance motorsports for lightweight, robust parts. Its versatile properties make Ti6Al4V Grade 23 a preferred choice across these advanced industries.

Ti-6AI-4V Grade 23

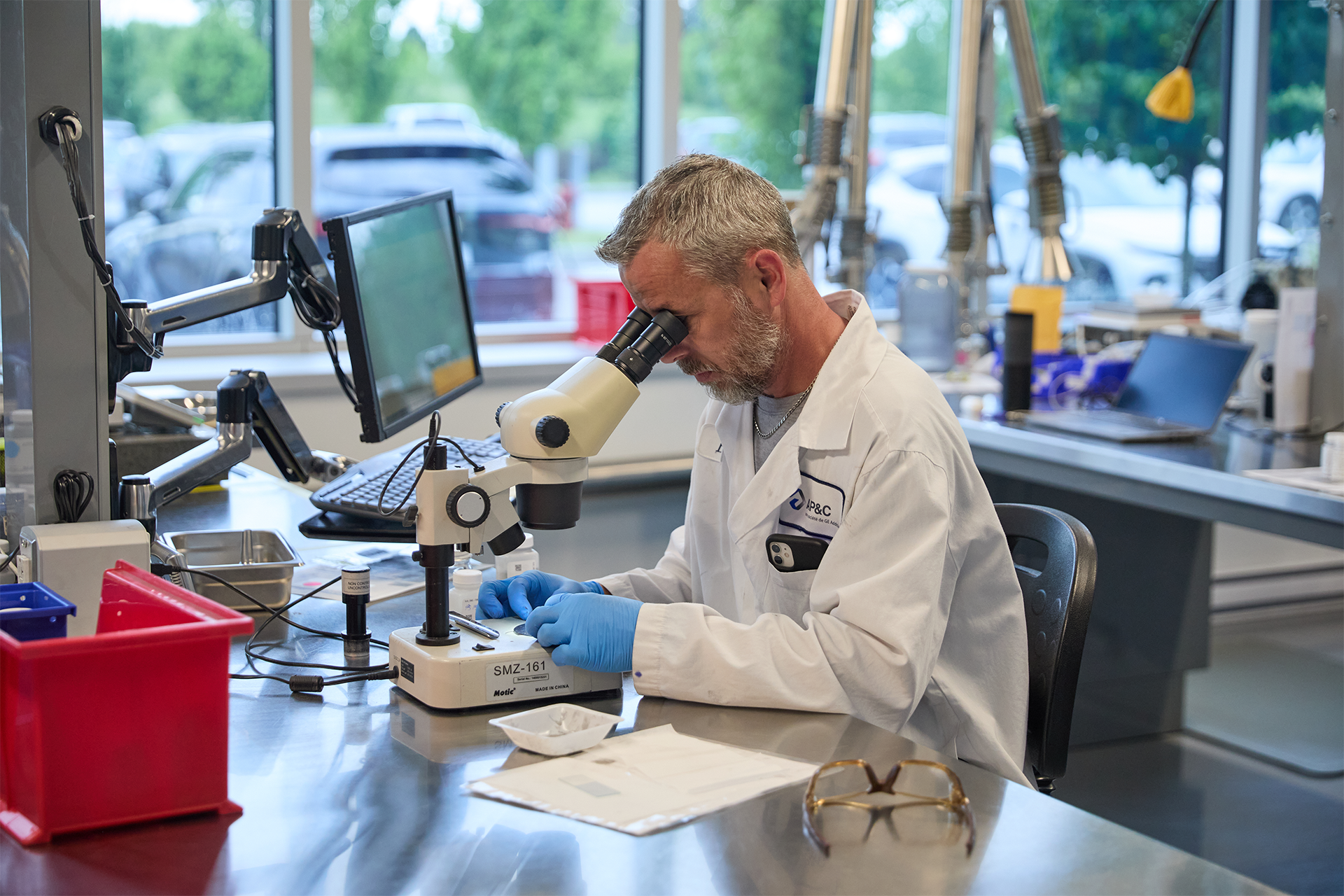

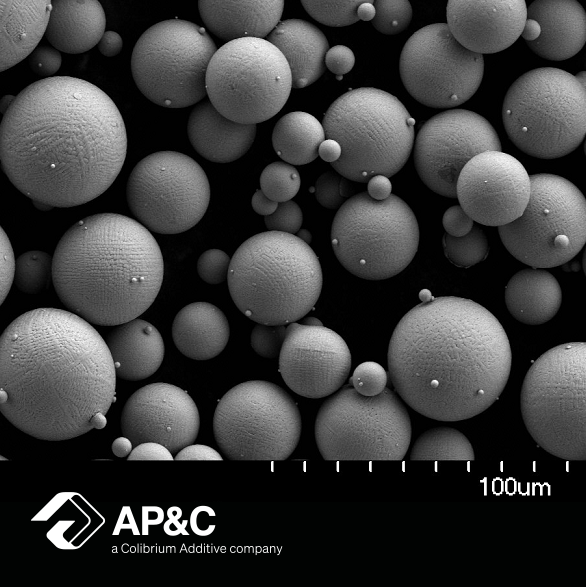

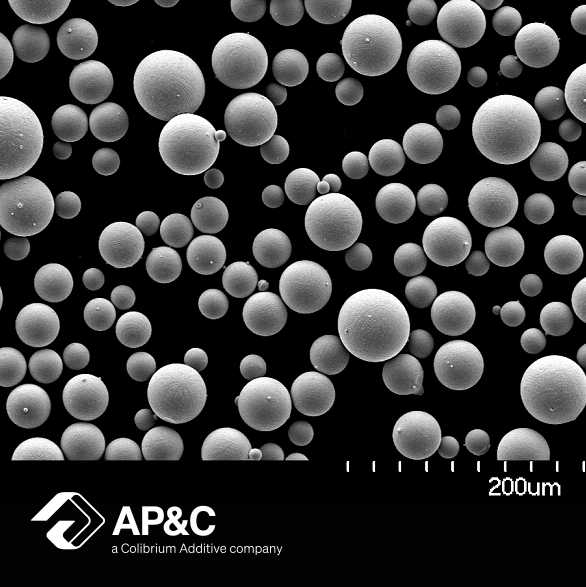

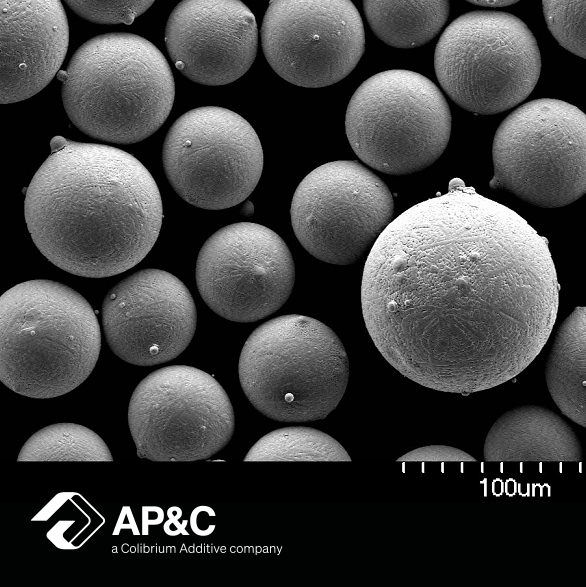

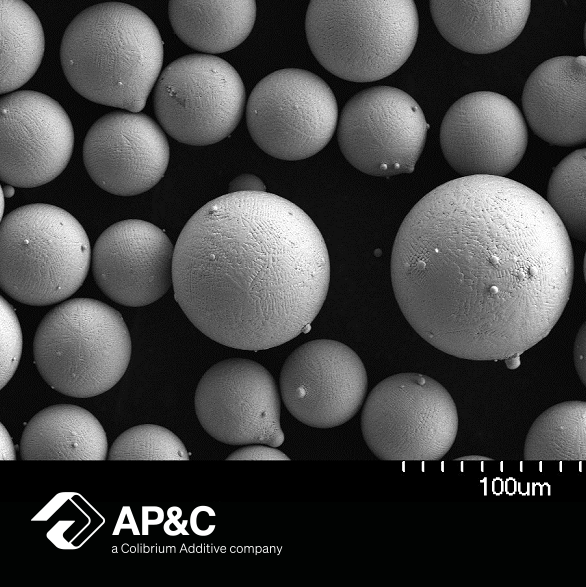

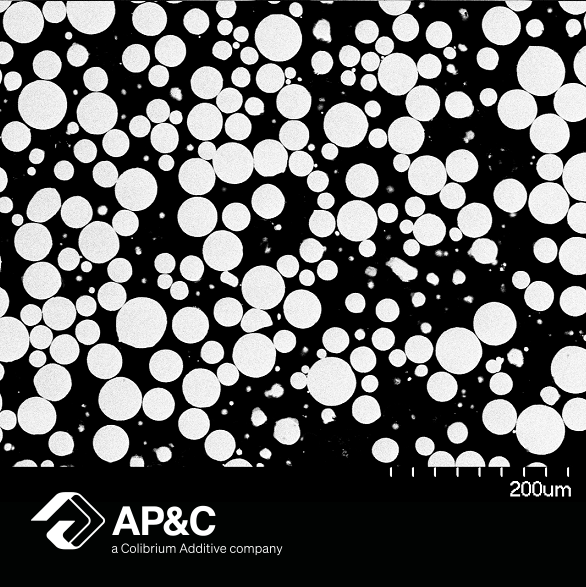

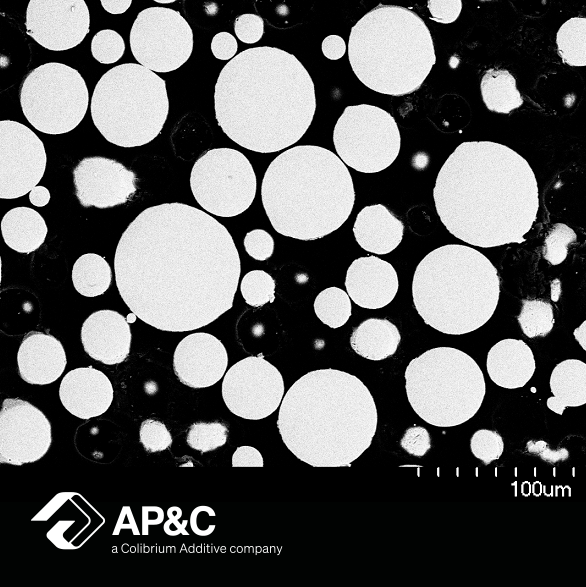

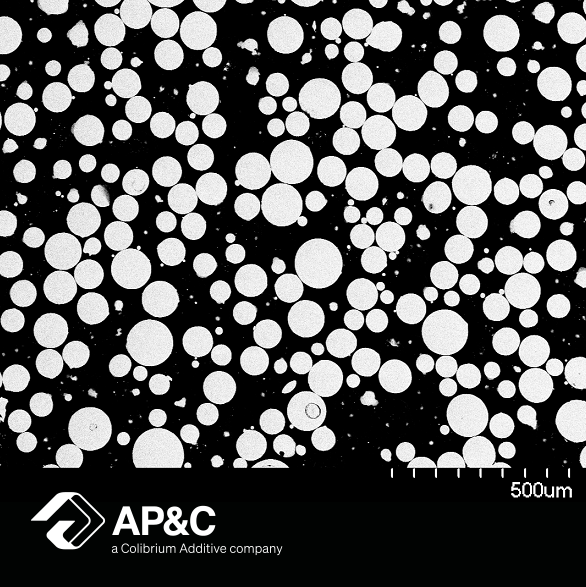

Since 2006, experienced users of Additive Manufacturing, MIM, PM-HIP, Binder Jet, and Coating technologies have trusted AP&C’s Ti-6Al-4V powders, which are manufactured using the proprietary APATM Plasma Atomization process. These highly spherical powders contain virtually no entrapped porosities. Additionally, they possess minimal satellite content, resulting in exceptional flowability and packing density.

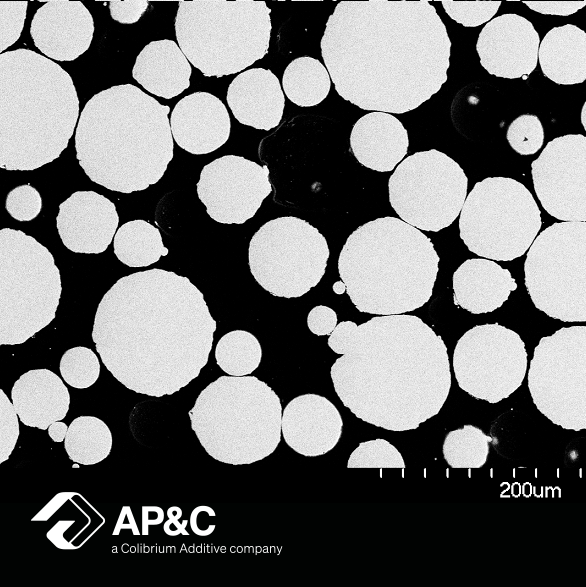

Metallographic images

15-45 µm

20-63 µm

45-106 µm