Titanium Aluminide

TiAl

Titanium aluminide: TiAl

Ti-48Al-2Cr-2Nb

TiAl is a new class of aerospace alloys that offers an excellent strength-to-weight ratio as well as high chemical and thermal stability. Gamma titanium aluminide alloy has excellent mechanical properties as well as oxidation and corrosion resistance at elevated temperatures (over 600 degrees Celsius). TiAl is the latest class of materials competing with Nickel superalloys for the fabrication of aircraft engine parts such as low-pressure turbine (LPT) blades.

Powder chemical composition may comply with standards: AMS7023 or equivalent standard

Powder chemical composition may comply with standards: AMS7023 or equivalent standard

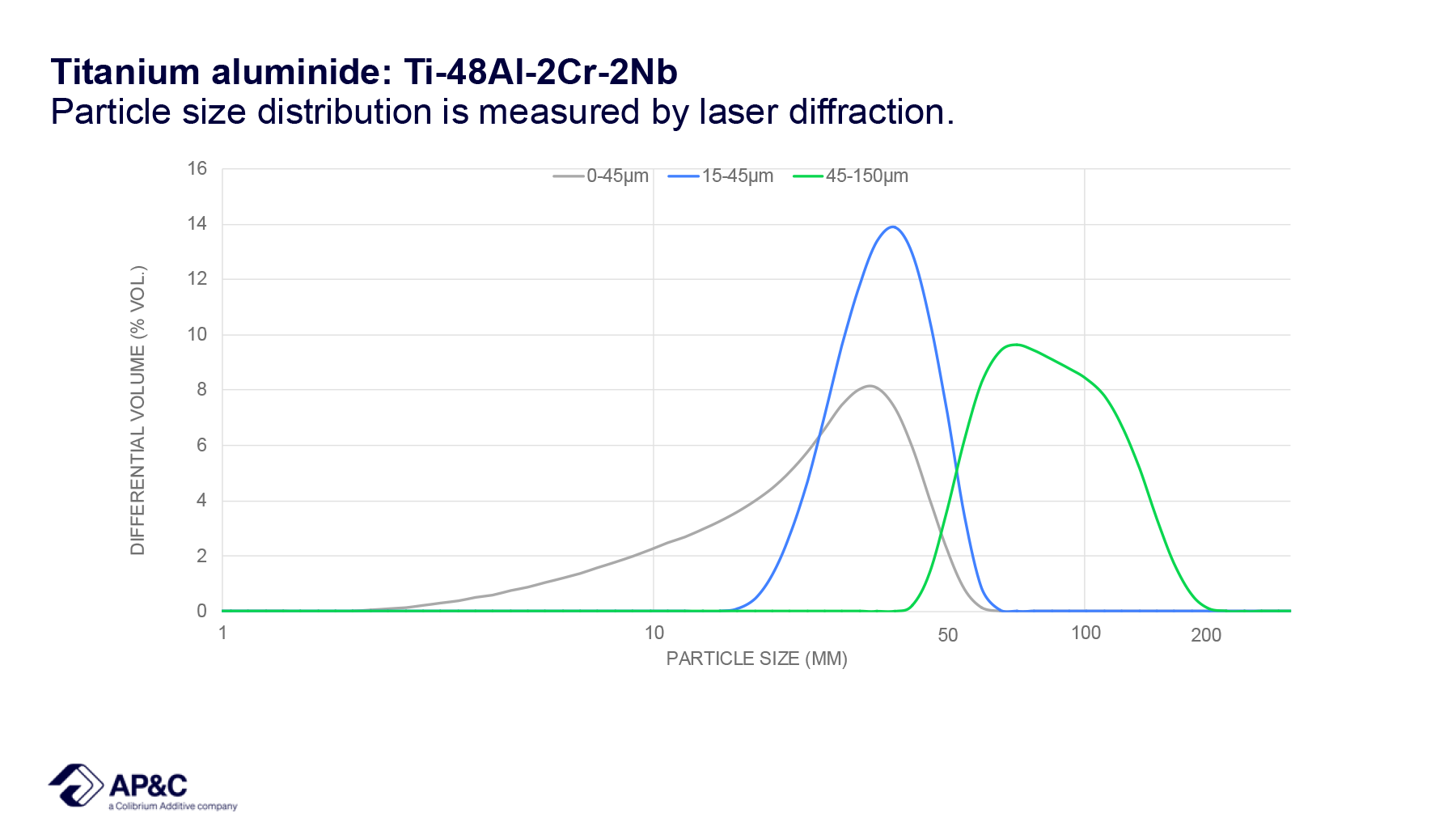

Particle size distribution

15-45µm

45-150µm

Typical values

PSD

Size distribution by laser diffraction (ASTM B822)

Apparent density (ASTM B212)

Flow rate (ASTM B213)

Oxygen Content

Technology application

D10

D50

D90

45-150 µm

55 µm

83 µm

130 µm

2.20

g/cm 3

g/cm 3

32 s

0.05 w%

EB-PBF

Various particle sizes are available upon request.

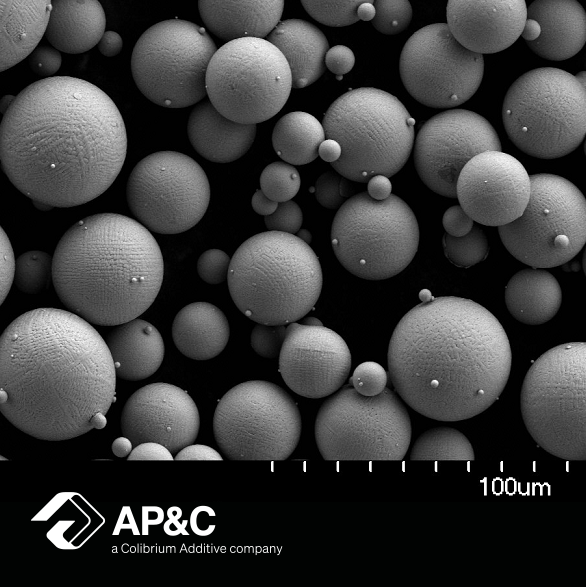

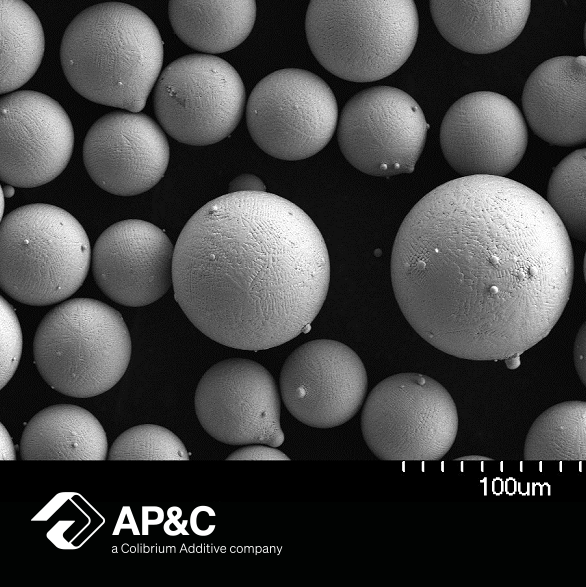

TiAl powders are created at AP&C using its proprietary plasma atomization process. The plasma atomization process has a high degree of controllability and uses plasma torches to transform the raw material or liquid metal stream into a powder

After atomization, the powder is sieved according to customer specifications.

Titanium Aluminide (TiAl) is one of the most challenging metal alloy powders within additive manufacturing, yet increasingly customers are realizing its potential for high-end applications where performance is key.

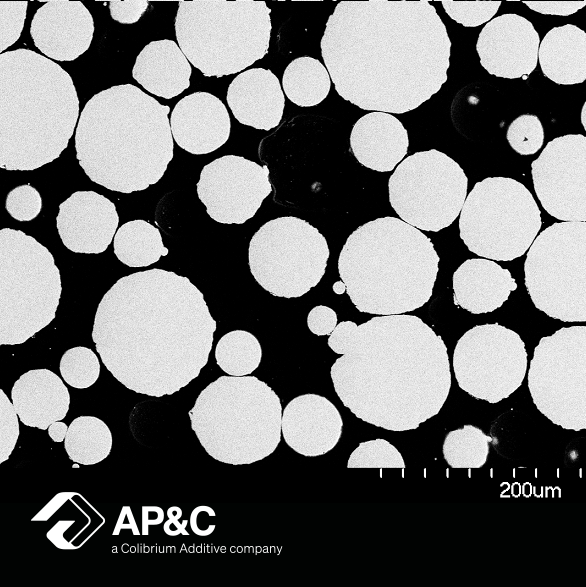

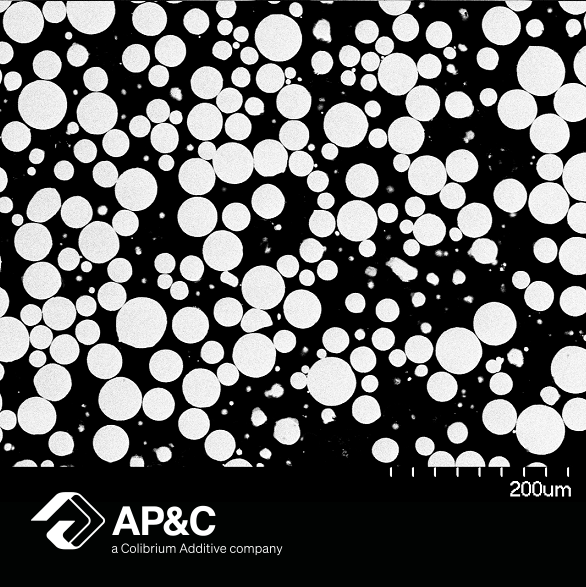

Metallographic images

15-45µm