Niobium Alloy

C-103

Niobium

C-103

Niobium C103 is a high-performance, niobium-based alloy that primarily consists of niobium (Nb) with additions of hafnium (Hf) and titanium (Ti). This alloy is well-known for its excellent high-temperature strength and oxidation resistance, making it suitable for extreme environments. Its primary use in the aerospace industry, particularly in rocket engines and spacecraft, underscores its importance in advanced engineering fields. The alloy's unique properties also make it valuable in gas turbines, nuclear reactors, and various high-temperature industrial applications.

Powder chemical composition may comply with standards: ASTM B652, AMS7852, AMS7857or equivalent standard

Powder chemical composition may comply with standards: ASTM B652, AMS7852, AMS7857or equivalent standard

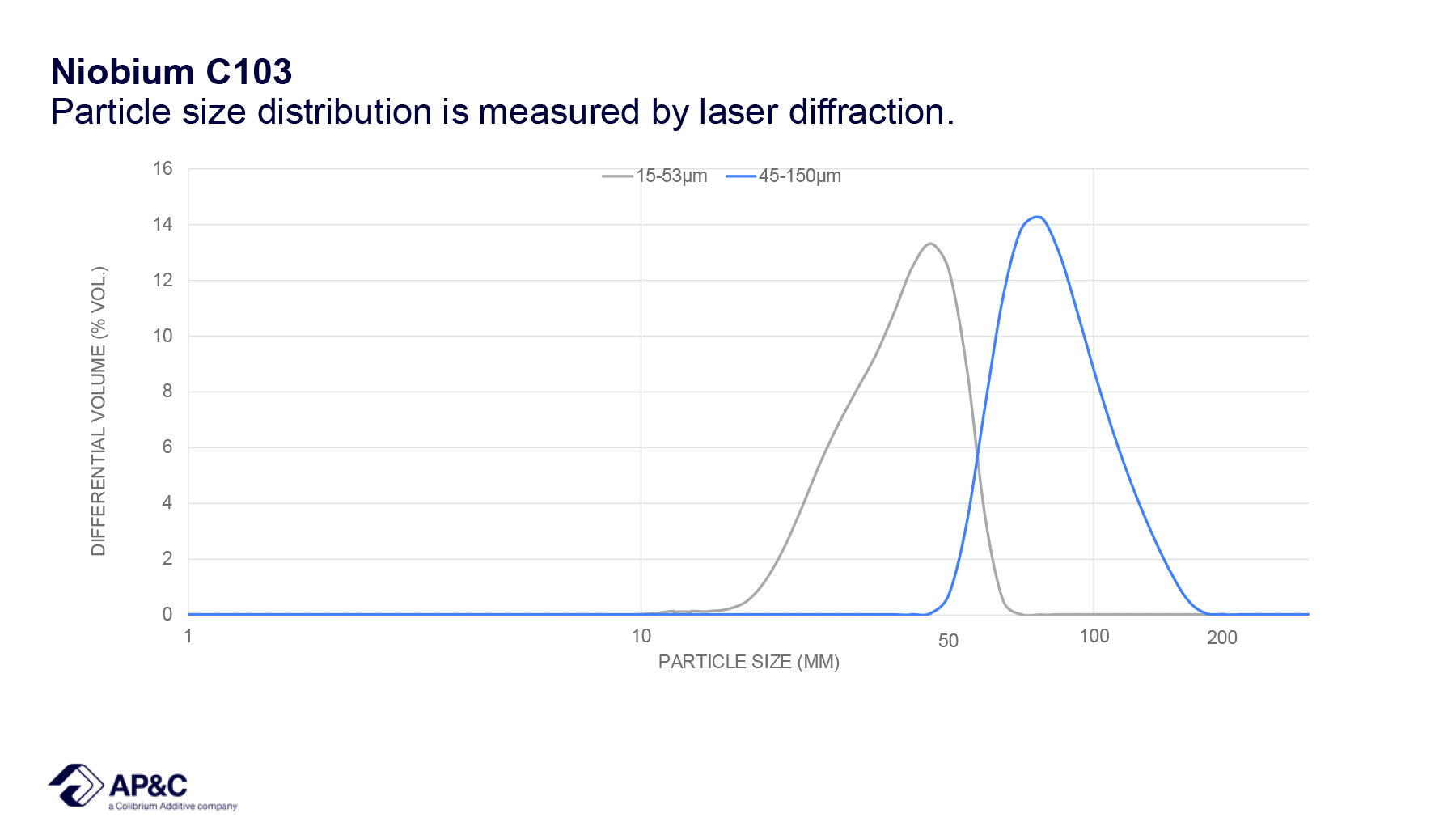

Particle size distribution

45-150µm

Typical values

PSD

Size distribution by laser diffraction (ASTM B822)

Apparent density (ASTM B212)

Flow rate (ASTM B213)

Oxygen Content

Application technology

D10

D50

D90

15-53 µm

24 µm

38 µm

52 µm

4.97

g/cm 3

g/cm 3

13 s

0.030 w%

L-PBF

45-150 µm

62 µm

83 µm

130 µm

5.13

g/cm 3

g/cm 3

11 s

0.018 w%

EB-PBF, L-PBF, DED

Various particle sizes are available upon request.

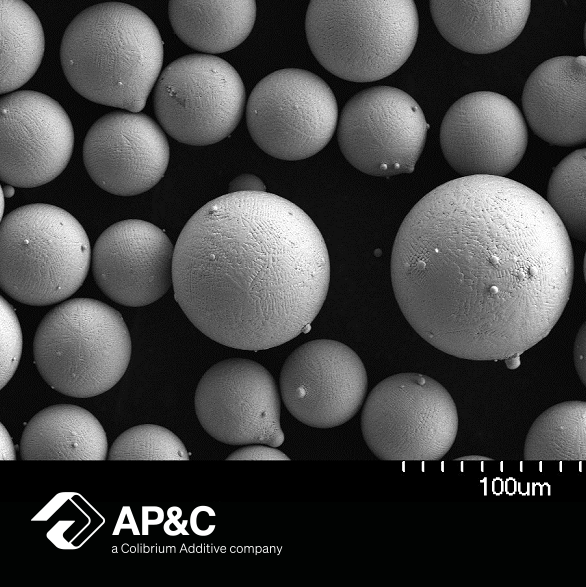

AP&C’s spherical Niobium C103 powders possess the ideal characteristics for various powder metallurgy technologies, include Additive Manufacturing. The powders are produced using the patented APATM Plasma Atomization process, which was designed specifically for atomization of high-temperature metals, such as Niobium alloys. With a large industrial capacity for Niobium Alloys powder production, AP&C can support high-volume industrial applications.

After atomization, the powder is sieved according to customer specifications.

Since 2006, experienced users of Additive Manufacturing, MIM, PM-HIP, Binder Jet, and Coating technologies have trusted AP&C’s powders, which are manufactured using the proprietary APATM Plasma Atomization process. These highly spherical powders contain virtually no entrapped porosities. Additionally, they possess minimal satellite content, resulting in exceptional flowability and packing density.

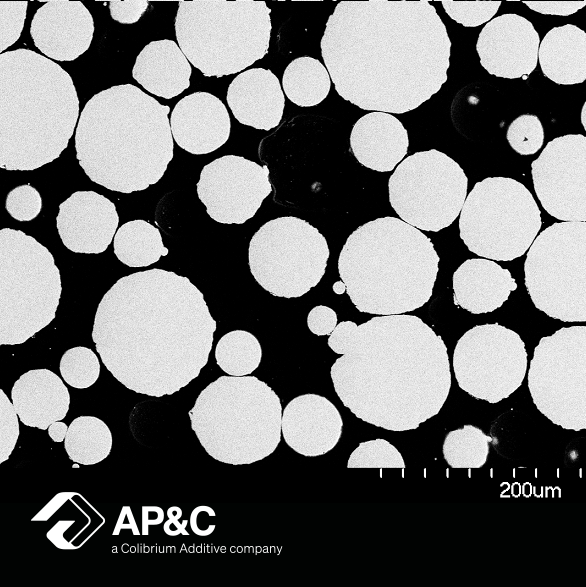

Metallographic images