Commercialy pure titanium

Cp-Ti Grade 1

Commercialy pure titanium

Cp-Ti Grade 1

CpTi Grade 1 is a commercially pure titanium. It is the most malleable and corrosion-resistant among all the commercially pure Ti grades, though it has the lowest strength. Common uses for CpTi Grade 1 include medical devices, airframe construction where high formability is essential, and applications requiring corrosion resistance in the chemical and marine industries.

Powder chemical composition may comply with standards: ASTM B348, ASTM F67, ASTM F1580 or equivalent standard.

Powder chemical composition may comply with standards: ASTM B348, ASTM F67, ASTM F1580 or equivalent standard.

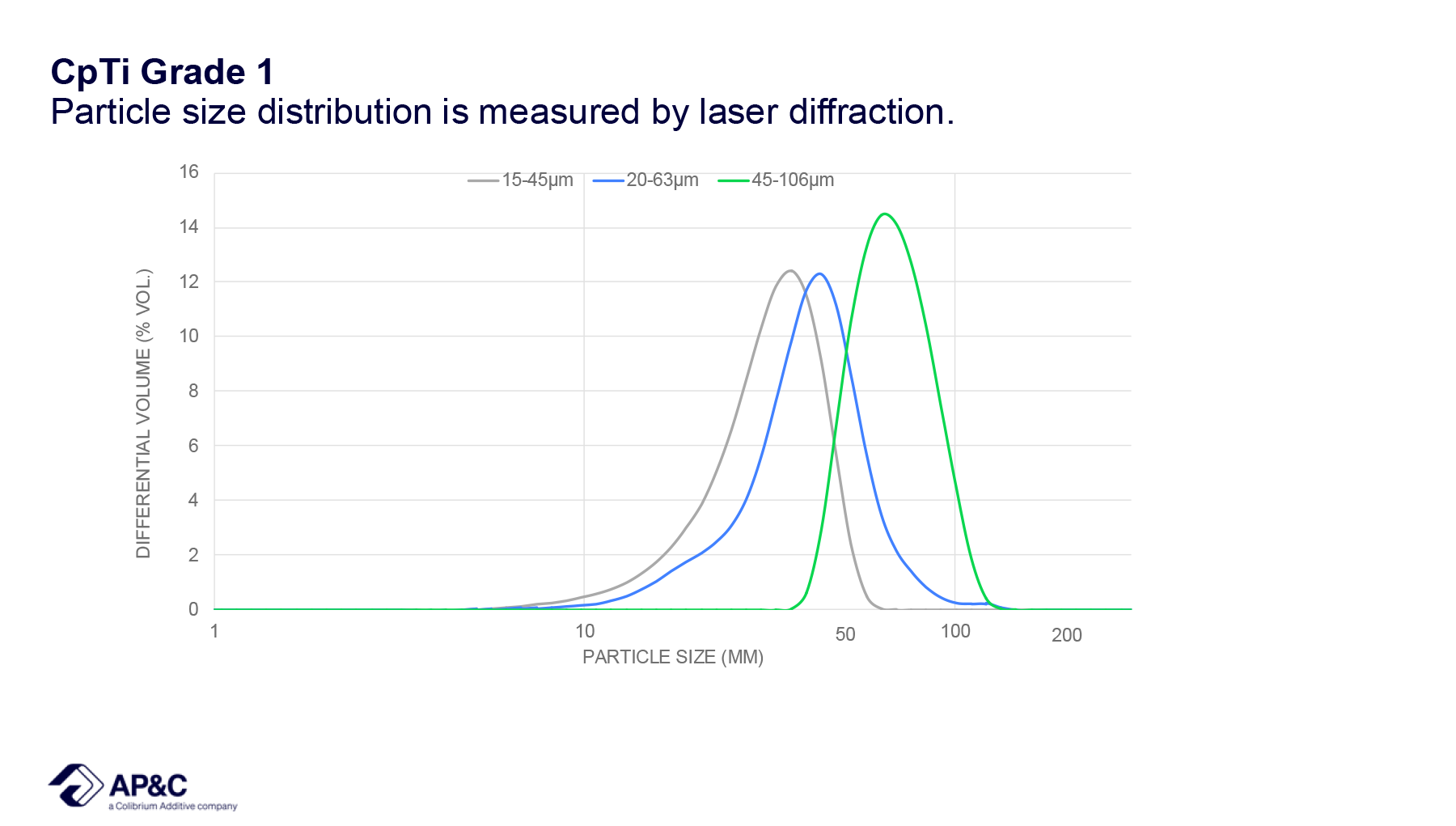

Particle size distribution

15-45 µm

20-63µm

45-106 µm

Typical Values

PSD

Size distribution by laser diffraction (ASTM B822)

Apparent density (ASTM B212)

Flow rate (ASTM B213)

Oxygen content

Application Technology

D10

D50

D90

15-45 µm

17 µm

32 µm

44 µm

2.55g/

cm 3

cm 3

29 s

0.16 w%

L-PBF

15-53 µm

20 µm

41 µm

54 µm

2.60

g/cm 3

g/cm 3

29 s

0.15 w%

L-PBF

20-63 µm

22 µm

43 µm

60 µm

2.56

g/cm 3

g/cm 3

27 s

0.12 w%

L-PBF

45-106 µm

50 µm

74 µm

100 µm

2.61

g/cm 3

g/cm 3

25 s

0.10 w%

EB-PBF, DED

Various particle sizes are available upon request

Pure Titanium powders, commonly known as CpTi (Commercially pure titanium), are used extensively in the medical field due its biocompatibility and lack of potentially harmful alloying elements, is especially useful for medical devices and non-load bearing devices such as medical implants or trauma plates.

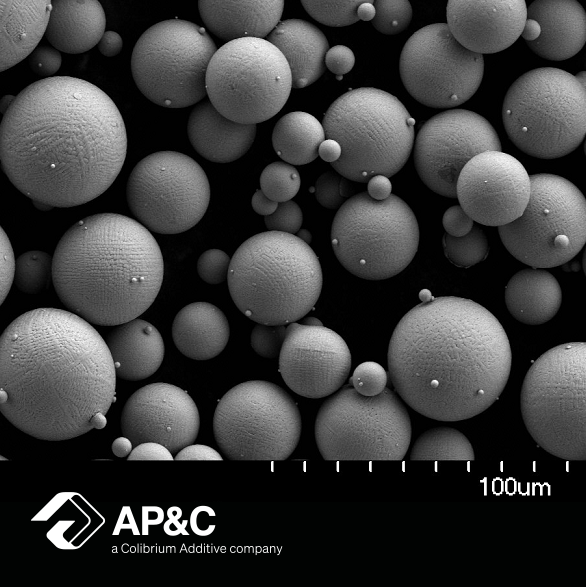

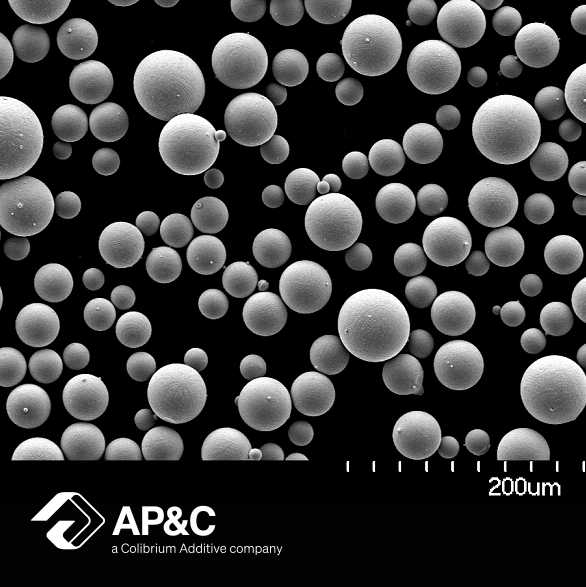

After atomization, the powder is sieved according to customer specifications.

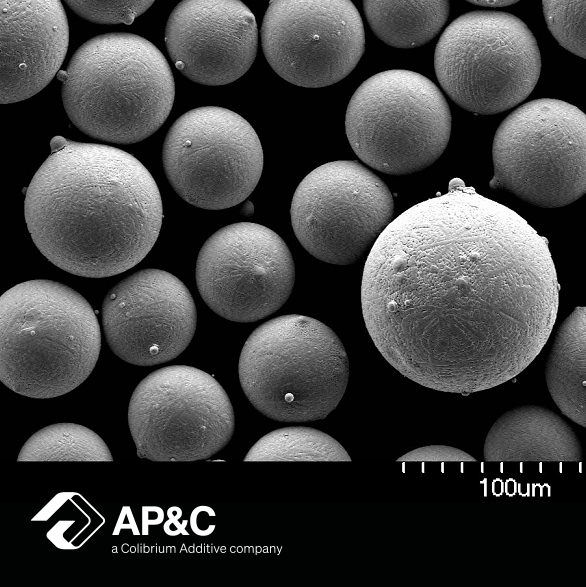

AP&C is an ISO 13485 accredited supplier and commits to meet the highest quality standards for medical applications, while offering premium-quality powders, that are high in purity and batch-to-batch consistency. AP&Cs APATM plasma-atomized CpTi powders also feature high-sphericity, low levels of entrapped and surface porosities, and minimal satellite content.

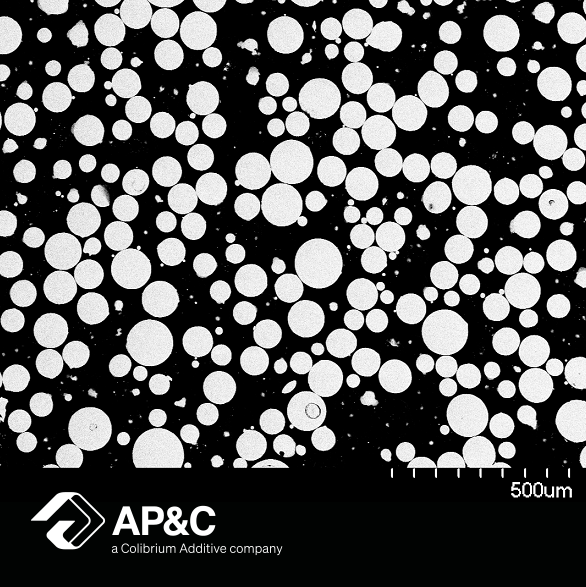

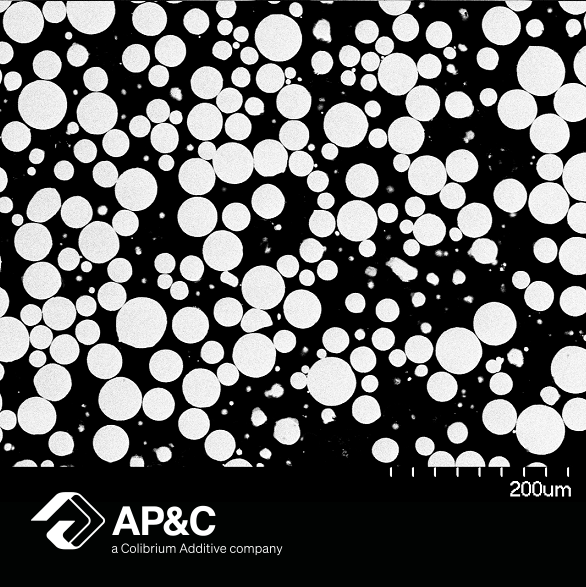

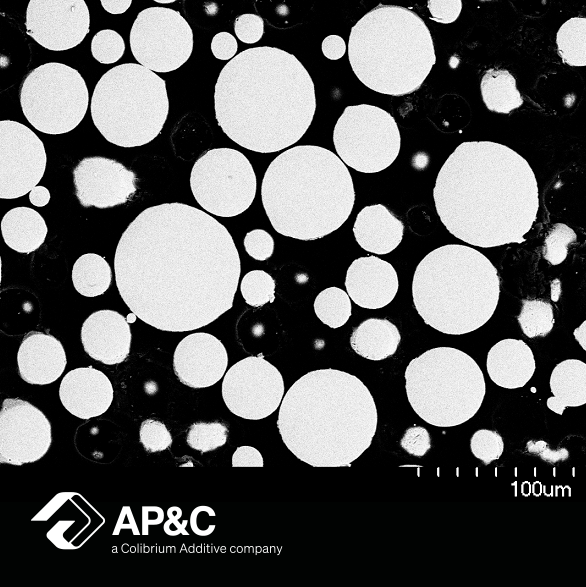

Metallographic images

15-45 µm

20-63 µm